Rewind a few days, I had cut the big hole in Holiday in preparation for installing the propane locker I built the week before. There were a few more tasks I needed to complete before wrestling the locker below and bolting it in place. First, I drilled yet another hole in Holiday. This one for vent hose for the bottom of the locker to take any dangerous propane over board and out of Holiday. The hole was small but very close to the water line. I checked about 10 times before drilling not wanting to witness my dreams sinking at the dock! All went well, and I installed a thru hull and attached the hose. The other end of the hose goes to a fitting epoxied in a hole I drilled at the bottom of the locker. All vapor tight to the rest of the boat.

But before I drilled the hole for the vent in the locker, I had to wrestle it finally into place. The locker is actually bigger than the hole drilled in the seat and bigger than most entry points into the boat for that matter. I had to take it into the cabin, back into the quarter berth, open some engine access panels, then squeeze (and I mean squeeze!) it over and behind the engine. Then, I had to crawl into a different cockpit locker, shuffle it along the bilge of the boat, and remove a steering cable, before finally getting it up and in contact with the bottom of the seat where the hole is. It was a pain! But then finally, a few pilot holes with Lindy’s help, a little caulking, and the locker was bolted into place! A week ago, I would never thought we would get this far.

Oh, and I took a picture of this piece of the deck to show what the fiberglass deck and balsa core looks like that I described back in this post. Pretty much the whole boat is constructed like this.

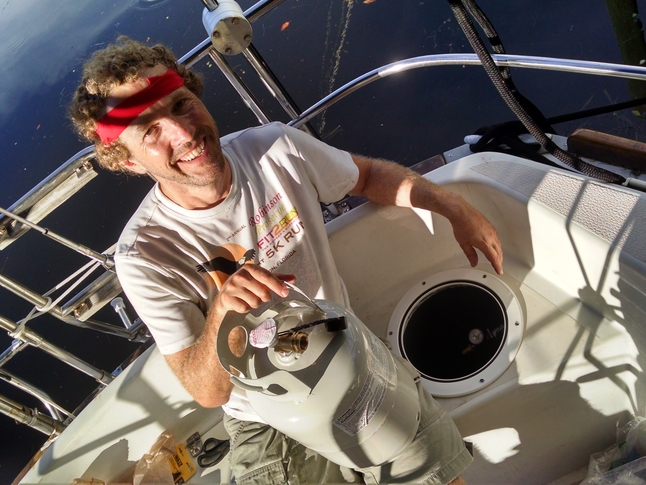

As if the project hadn’t been tough enough, this next part was really rough. We had to run the hose through Holiday from the locker to the stove and also the wires for the solenoid switch installed next to the stove. Sounds easy enough, but let me tell you, I was in a lot of areas where I could only get one hand to what needed to be zip tied to the routing areas. Try zip tying with one hand over and behind your head while also holding the two things you are zip tying together with that one hand. And then try to do that about 30 times while you are crammed into lockers that you barely fit in. Did I mention it was also a million degrees outside. It was frustrating and exhausting to say the least. But, like everything else, we finally got it done and were getting very close to finishing the project. Lindy even made me a head band because sweat kept getting in my eyes. Loved the Bruce Leroy look 🙂

The solenoid even came right on. Guess I wired it right! You can also see the propane sensor (small black box near the floor) in the solenoid control panel (grey box up top) pic. If it senses propane, an alarm goes off and the solenoid shuts. We tested it with an unlit lighter, and it worked great.

Wow! 10 full days of bustin’ it on this project, and it’s finally done. It’s been tough, but I’ve found I really enjoy boat projects like this. I’ve also lost 10 lbs since leaving the desk job to boot. Probably about half of that due to this propane locker. Time for us to start using it and fatten me back up!

We pressurized the system, and checked for leaks. Didn’t find any, so I guess I nailed that instruction “don’t over tighten the fittings.” No way that could be subjective and misinterpreted. Check out that flame!

I had an idea for a spare tank holder and knocked it out too. Basically just cut a boat fender in half and install a fender holder outboard of the cockpit. Seemed to work pretty good. You can see the cover that Lindy made in action too! These tanks are 11 lb, half the size of the regular exchange ones for gas grills. From what I’ve read, the 2 tanks should last us 4-6 months. So, won’t have to be constantly searching for refill stations, and we can also stay off the grid for extended periods when we feel like it. All that’s left now are a few small projects, clean and organize the boat, and set sail!

Rita Wiggins

September 22, 2016 at 9:23 pmWow, talking about tedious, glad that is done and behind y’all , hope it will be smooth sailing from here on out! A lot of hard work by both of y’all.

Denise

September 23, 2016 at 10:15 amAwesome job! Looks great. Bet you are glad that project is done.

Dave Duncan

September 26, 2016 at 12:30 amThe locker looks very professional. Looks like you paid attention to every detail. Great job. – Dad

Sarah Belcher

September 29, 2016 at 4:39 pmHi Zach, I also own a Tartan and have been wondering what to do about creating a independent gas locker. What you’ve created looks great! Could you let me know what the dimensions were? What size bottle are you using (it looks quite small)? If you can recommend any designs or plans I’d really appreciate it. We would like to have a large bottle as we are departing from NZ but regulations here require independent lockers or transom hung bottles. We currently have a Mar Gas system which is sealed but isn’t approved here in NZ.

Cheers,

Sarah

zdunc

September 29, 2016 at 6:15 pmHey Sarah, the fiberglass pipe that is the body is 12″ inside diameter, 13″ outside diameter and about 19″ tall. The box off the side for the regulator is 3.5″ deep, 5″ wide and 7″ tall. The bottle is an 11 lb Worthington. It is the largest size that will fit in the area I used. With the second tank off the rail, I think we’ll get 4-6 months. I mostly followed the instructions on the Tartan 37 owners site, http://www.tartan37.com/T37TRC4S2.pdf. I also documented in detail on the owners forum the changes, struggles, and insights regarding the instructions and the build, http://www.tartan37.com/t37forum/viewtopic.php?f=5&t=1204&st=0&sk=t&sd=a&sid=74274f69a6b2e405678de47dca63c7f0&start=0. Check all that out, and let me know if you have any questions.

Michael Crowe

September 11, 2022 at 1:22 pmHello, my name is Michael Crowe. Becky and I own Tartan 37 gracefull. Would you please post a list of the parts and where they are available for the propane locker installation.

Sincerely

Michael Crowe

zdunc

October 22, 2022 at 3:54 pmHey Michael, I did a long post with those on the Tartan owners forum. Let me see if I can find that and repost. Zach

zdunc

October 22, 2022 at 4:05 pmHere is a link to my post:

http://www.tartan37.com/t37forum/viewtopic.php?f=5&t=1204&st=0&sk=t&sd=a&hilit=Propane&sid=ca15487ff14986a422f7f7d0a3480ede

Here is a link to the original instructions I was following that I reference:

http://www.tartan37.com/T37TRC4S2.pdf